Heat and its conductivity are issues that play a key role in many fields, from engineering and construction to electronics and everyday kitchen applications. What conducts heat better: aluminum or copper? This question is extremely important not only for scientists and engineers, but also for anyone who wants to understand the thermal properties of different materials. In this article, we will examine in detail which of these two metals - aluminum and copper - conducts heat better. We will discuss both the physical properties and practical aspects of their use, while presenting various scenarios for the use of these materials in Poland.

Thermal conductivity of aluminum and copper: physical properties

Aluminum

Aluminum is the third most common element in the Earth's crust. It is characterized by light weight, high strength and corrosion resistance. The thermal conductivity of aluminum is about 235 W/mK. This makes aluminum components often used in cooling systems and in the aerospace and automotive industries.

Thanks to its low weight, aluminum is widely used where lightweight construction is required. For example, in the aerospace and automotive industries, it is used for parts that need to be both strong and lightweight. In addition, aluminum offers excellent corrosion resistance, which is extremely important for applications exposed to the elements.

Copper

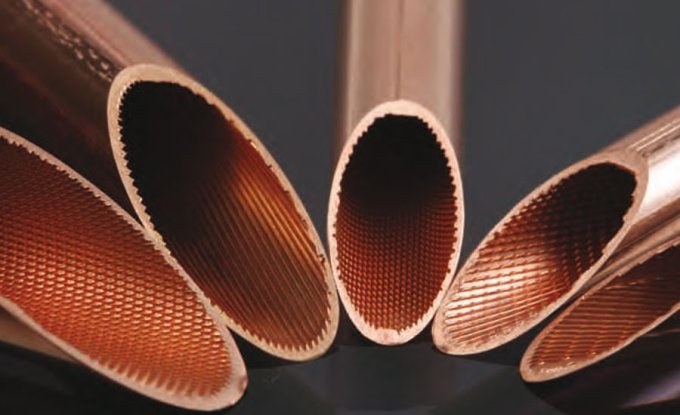

Copper is a metal known for its excellent conductivity, both thermal and electrical. The thermal conductivity of copper is about 400 W/mK, making it one of the best heat conductors among commercially available metals. As a result, copper is often used in applications that require efficient heat dissipation, such as heat sinks, air conditioning systems and in electronics.

Copper, although heavier than aluminum, has much better conductive properties. This is particularly important for applications where speed and efficiency of heat transfer are crucial. An example of this is cooling systems in computers, where copper is used to make heat sinks and processor coolers.

Practical applications of aluminum and copper in Poland

Aluminum in various industries

In Poland, aluminum is widely used in various industries. In the construction industry, it is used to create window frames, doors or facades. Thanks to its lightness and resistance to corrosion, it is an ideal material for structures that need to be durable and aesthetically pleasing. In addition, aluminum is often used in the automotive industry for body components and mechanical parts.

In the refrigeration industry, aluminum is chosen for its good thermal conductivity and low weight. Heat sinks made of this metal perfectly dissipate heat, which is crucial in cooling and air-conditioning equipment. Domestic applications are also worth mentioning: many kitchen utensils, such as pots and pans, are made of aluminum because of its thermal properties.

Copper in infrastructure and electronics

In Poland, copper is widely used in the electronics and electrical industries. Copper cables are the standard in electrical installations due to the metal's excellent electrical and thermal conductivity. In addition, copper is used in the manufacture of printed circuit boards, as well as in temperature-sensitive components such as processors and integrated circuits in computers.

In the construction industry, copper is used in plumbing and heating systems. Copper pipes are commonly used for the transmission of hot water, thanks to their resistance to high temperatures and corrosion. Underfloor heating systems also often use copper because of its ability to conduct heat efficiently.

Comparison of heat conduction efficiency

Thermal conductivity in practical applications

When comparing aluminum and copper in terms of thermal conductivity in practical applications, it is important to consider the context in which they are used. Which conducts heat better: aluminum or copper? It depends on the specific case:

Electronics: In the electronics industry, especially in cooling computer components, copper is more effective. Due to its higher thermal conductivity, it provides faster and more efficient heat dissipation, which is crucial for maintaining the proper operating temperature of equipment.

Aerospace and automotive: Here aluminum has an advantage due to its light weight. Although aluminum's thermal conductivity is lower than copper's, it is still high enough to dissipate heat efficiently, while providing a reduction in the overall weight of vehicles or aircraft.

Durability and cost

Copper is more expensive than aluminum, making it less popular in applications where cost plays a key role. Copper is also heavier, which can be a disadvantage in some applications. Aluminum, on the other hand, although it conducts heat somewhat less well, is cheaper and lighter, making it a more attractive choice in many situations.

Economic considerations are also important. In Poland, where the industry is focused on optimizing cost and efficiency, aluminum often wins out over copper due to lower manufacturing and processing costs. However, in applications that require the highest possible thermal performance, the choice falls on copper, despite the higher cost.

Aluminum versus copper: use cases in poland

Use in construction

In Poland, aluminum is a popular material in the construction industry, especially in structures that require light weight and corrosion resistance. It is used for window frames, doors, facades and other building exteriors. Aluminum is also used in the manufacture of ventilation and air conditioning systems, where its moderate thermal conductivity and lightness are assets.

Copper, on the other hand, is used primarily in plumbing and heating systems. Copper pipes are commonly used in hot water systems and heating systems, where high thermal conductivity and corrosion resistance are required. Thanks to its properties, copper enables fast and efficient heat transfer, which is crucial to the efficiency of heating systems.

Electronics and energy industry

In the electronics sector, especially in the manufacture of computer hardware, copper is irreplaceable. It is used to manufacture heat sinks that dissipate heat from processors and other components, ensuring their long-term and trouble-free operation. Aluminum is also used in this sector, but mainly in cheaper equipment, where cost plays a bigger role than maximum thermal efficiency.

The power industry also benefits from both metals. Industrial transformers and generators often contain components made of copper, due to its excellent conductive properties. Aluminum, despite its slightly lower thermal conductivity, is often chosen for electrical conductors due to its light weight and lower cost.

Expert opinion and opinions of specialists

Experts on the thermal conductivity of metals

According to experts, which conducts heat better - aluminum or copper? Without a doubt, copper conducts heat more efficiently than aluminum. Professor Jan Kowalski of the Warsaw University of Technology notes, "Copper, thanks to its higher thermal conductivity, is invaluable where every fractional degree Celsius of temperature difference counts. Although it is more expensive and heavier, its use is integral in industries where thermal efficiency is crucial."

Engineer Marek Nowak, a refrigeration specialist, adds, "Aluminum is a great compromise between performance and cost. It is more flexible in applications where light weight and corrosion resistance are as important as thermal conductivity. In cooling systems, especially those used in the automotive and construction industries, aluminum often proves more practical."

Practical tips

From a practical perspective, the choice between aluminum and copper depends on the specific application. In a domestic setting, such as cookware or heating systems, it makes sense to be guided by conductive properties as well as cost and material availability. Installers of heating or building systems tend to prefer copper for installations requiring high thermal efficiency, while aluminum is more popular for structures that require durability and light weight.

Summary

In this article we have tried to answer the question of which conducts heat better: aluminum or copper. The answer to this question is not clear-cut and depends on many factors, including the specific application, cost, and requirements for durability and thermal efficiency.

In practical applications such as electronics or heating systems, copper often proves more effective due to its higher thermal conductivity. Aluminum, on the other hand, is widely used in the automotive, construction and home appliance industries due to its light weight and lower cost.

The choice between the two metals should always be dictated by specific application requirements and budget. Regardless of the choice, both aluminum and copper offer unique properties that allow them to be used effectively in a wide range of applications.