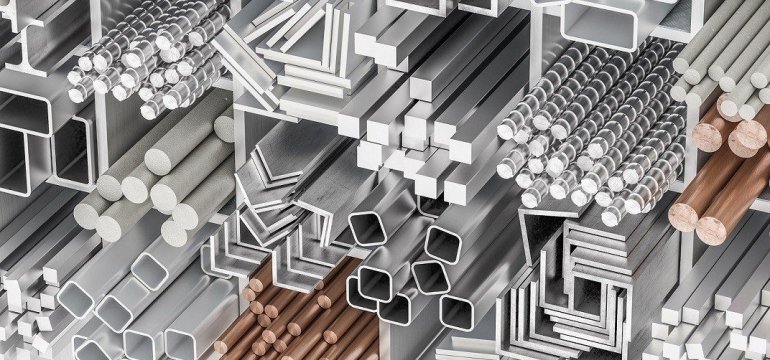

In today's technologically evolving world, steel and stainless steel play an important role in a wide range of industries, from the construction industry to the manufacture of household goods. Both of these forms of metal have their own unique properties that make them indispensable in various applications. However, how do you tell the difference between steel and stainless steel? This question is asked by many people, both professionals and DIY amateurs. In this article, we will look at the various methods that help identify these two commonly used materials. We will focus on the Polish context, presenting specific information that will help to understand and properly apply the knowledge of how to distinguish between steel and stainless steel.

Differences in chemical composition: a basis for identification

Regardless of their similarities, steel and stainless steel differ significantly in their chemical composition. Steel consists mainly of iron with the addition of carbon (from 0.02% to about 2%), which enables it to regulate its hardness and strength. In addition, other elements such as manganese, silicon, phosphorus and sulfur may be present.

Stainless steel, on the other hand, is a type of alloy steel that contains at least 10.5% chromium, which gives it corrosion resistance. Chromium forms a thin layer of chromium oxide on the surface of stainless steel, which prevents further oxidation. In addition to chromium, other additives such as nickel, molybdenum or titanium may be present in stainless steel to further improve its properties.

Identification by chemical analysis

One of the most direct ways how to distinguish between steel and stainless steel is to perform a chemical analysis. This can be done with equipment such as an X-ray spectrometer or portable chemical analysis facilities (XRF). These tools allow you to quickly and accurately determine the chemical composition of a sample. In practice, however, such methods are mainly used by laboratories and heavy industry.

Magnet testing: a simple test for blacksmiths and do-it-yourselfers

At home, a fairly simple test of how to distinguish steel from stainless steel is the magnetism test. Carbon steel (the most basic type of steel) is magnetic, meaning that it attracts a magnet. Stainless steel, on the other hand, is not always magnetic. Stainless steel types, such as austenitic (e.g., type 304 steel), are non-magnetic, while others, such as ferritic and martensitic, can exhibit magnetic properties.

Appearance and touch: simple visual evaluation methods

Another method of how to tell the difference between steel and stainless steel, especially in simple situations, is to carefully evaluate the external appearance and tactile characteristics of the metal.

Visual differences: surface and luster

Carbon steel is usually darker and duller than its stainless counterpart. It can rust and corrode, which often manifests itself as rust stains on the surface. On the other hand, stainless steel has a distinctive bright luster, which is often the result of brushing or polishing. It is less susceptible to corrosion, which makes it stay shiny for a long time.

Touch: checking hardness and smoothness

Touching the surface can also provide some clues. Carbon steel tends to be rougher and may show more roughness. Stainless steel tends to be smoother and cooler to the touch, which is clearly noticeable, especially at lower temperatures.

Practical applications: differences due to typical uses of steel

When analyzing how to distinguish steel from stainless steel, it is worth noting the typical uses of both materials. Daily experience and observation can help with identification.

Carbon steel applications

Carbon steel is widely used in construction (e.g., reinforcement, steel structures), tool making, automobiles, machine parts and many other mechanical applications. Due to its mechanical properties, such as strength and hardness, it is preferred where high durability is required.

Stainless steel applications

Stainless steel is often used where corrosion resistance is important, such as in the food, pharmaceutical and chemical industries, as well as in consumer products such as cookware, cutlery and interior finishes. Stainless steel is also popular in green energy applications, such as solar panels and wind turbines, because of its environmental friendliness and durability.

Laboratory techniques: advanced identification and analysis methods

When simple methods are not enough, more advanced laboratory techniques may be necessary to accurately determine whether a material is carbon steel or stainless steel.

X-ray spectrometry (XRF)

X-ray spectrometry is an analytical technique that can accurately determine the chemical composition of a metal sample. The device emits X-rays, which stimulate the atoms in the sample to emit their own radiation. By analyzing the spectrum of this radiation, it is possible to accurately identify the elements present. This tool is reliable and can identify even minute amounts of alloying additives.

Metallography

Metallography is a technique that analyzes the microcrystalline structure of a metal. A metal sample is polished and etched, and then analyzed under a microscope. Specialists can identify characteristic structures that are found only in stainless steel (e.g., characteristic austenite grains) or carbon steel (e.g., pearlite, ferrite).

The role of standards and certificates in identifying steel

Material certificates

In Poland, as in other countries, the metal industry is strictly regulated by norms and standards. Metal producers often provide material certificates that indicate the exact chemical composition, mechanical properties and production method of a given batch of steel. Such documents are extremely important, especially in applications where technical specifications must be accurately maintained.

European Union standards and directives

Compliance with standards is also crucial. The European Union, and by extension Poland, has various directives and standards for the quality and composition of metal materials, such as EN 10088 - standards for stainless steels. These standards not only help identify steel, but also ensure that the material meets certain requirements for strength, corrosion resistance and other properties.

Importance of experience of specialists in identifying steel and stainless steel

The role of experienced metallurgists and engineers

In addition to laboratory techniques, the professional experience of specialists can be invaluable. Metallurgists, materials engineers and metallurgical specialists often possess irreplaceable knowledge and intuition gained through years of working with different types of metals. The ability to quickly identify properties by visual inspection, touch or even the sound made by striking the metal is a valuable addition to instrumental testing methods.

Expert opinions and their practical advice

Also worth mentioning are the opinions of experts who stress the importance of routine training and education in metallurgy. In the words of Jan Kowalski, an experienced materials engineer from a Krakow metallurgical plant, "Without a proper understanding of the chemical composition and physical properties, it is difficult to realize the full potential of steel and stainless steel. Knowledge is the key."

Summary

How to tell the difference between steel and stainless steel is a question that may seem complicated at first glance. However, with the help of a variety of methods - from simple magnetic testing to visual assessment to advanced laboratory techniques - it is possible. Understanding the differences in the chemical composition, physical properties and typical applications of these materials can significantly help identify them.

Putting theoretical knowledge into practice, supported by the experience and intuition of specialists, is key to the proper identification and use of steel and stainless steel. Whether you are an engineer, a do-it-yourselfer or simply a curious enthusiast, with these tips in mind, you will certainly be able to distinguish between steel and stainless steel and put their unique properties into practice. In this way, you will not only guarantee a better quality of the projects you do, but also gain confidence that you are using the right materials for your intended purposes.