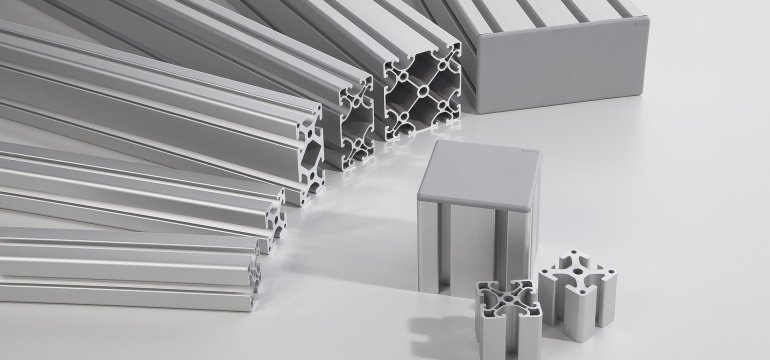

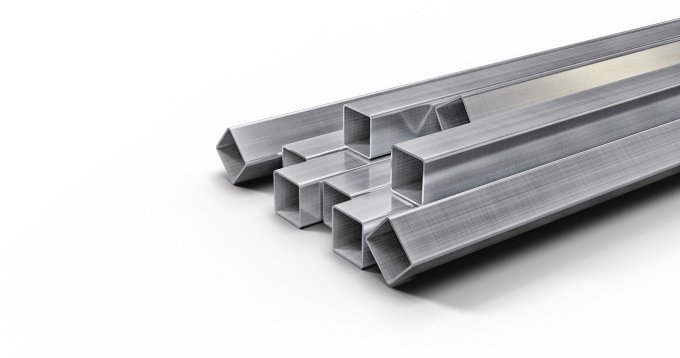

Aluminum is one of the most widely used materials in the construction, automotive or aerospace industries. Thanks to its properties, such as lightness, corrosion resistance and low heat conduction coefficient, aluminum profile is used in many fields. The key aspect that determines its usefulness is the strength of the aluminum profile. How to effectively evaluate and measure it? These questions will be answered in this article.

Strength of the aluminum profile: basic concepts and parameters

Understanding aluminum profile strength requires familiarization with several key concepts and parameters that are related to its mechanical properties. The most important of these are:

Tensile strength

Tensile strength, also known as Tensile Strength limit, is one of the fundamental parameters characterizing the strength of materials. It represents the maximum stress that a material can withstand before breaking. This measurement is extremely important, as it helps determine under what conditions an aluminum profile can be safely used.

Compressive strength

Another important parameter is compressive strength. It refers to the material's ability to withstand compressive forces. The aluminum profile must be able to resist deformation under heavy loads, especially in building structures.

Modulus of elasticity

Elastic Modulus is a measure of a material's elasticity that determines the material's ability to deform under load. In the case of aluminum profiles, a high elastic modulus means greater stiffness and less deformation under load.

Yield strength

Yield Strength is the point at which a material begins to deform plastically, meaning that it will not return to its original shape when the load is removed. It is an important indicator in assessing the durability and reliability of an aluminum profile.

Hardness

Hardness determines how resistant a material is to permanent surface deformation caused by a concentrated force, such as pressure or impact. Hardness is measured by various methods, but one of the most commonly used for aluminum is the Brinell method.

Methods for measuring the strength of an aluminum profile

There are many techniques and methods for measuring and evaluating The strength of an aluminum profile. The most important and commonly used of these are:

Mechanical tests

Mechanical tests are the basis for evaluating the strength of materials. The most common include:

Tensile testing

Tensile testing is one of the simplest and most commonly used methods for evaluating the The strength of an aluminum profile. In this test, a sample of the material is placed in a testing machine and then subjected to tensile forces until it breaks. Parameters such as tensile strength, yield strength and elongation are recorded by special sensors.

Compression test

Like the tensile test, the compression test involves subjecting a material sample to compressive forces. The aluminum profile is subjected to a compressive load, and the results, such as compressive strength and the resulting deformation, are analyzed.

Hardness test

The hardness of the material is evaluated using methods such as Brinell, Vickers and Rockwell. These tests involve pressing a small ball, pyramid or cone into the surface of the material under a specified force and measuring the deformation.

Numerical analyses

Numerical analyses, such as the Finite Element Method (FEM), are crucial in the process of evaluating the The strength of an aluminum profile. FEA allows the creation of digital models that reproduce the actual operating conditions of the profile. The results of these analyses provide detailed information that helps engineers design and optimize aluminum profiles.

Destructive and nondestructive testing methods

Destructive tests

Destructive tests, such as impact or fatigue tests, involve gradually increasing the load applied to the profile until it fails or breaks.

Non-destructive tests

Non-destructive tests, such as ultrasonic testing or penetrant testing, allow assessment of the the strength of an aluminum profile without damaging it. These techniques are particularly useful in quality control of finished products.

Application of aluminum profiles in Poland

The strength of the aluminum profile translates directly into its use in various industries. In Poland, the aluminum profile is widely used in such sectors as construction, automotive and aerospace.

Construction

In curtain construction, aluminum profile is used for windows, doors, facades or structural elements. Thanks to its strength and aesthetic appearance, aluminum is valued by engineers and architects alike.

Automotive

Aluminum profiles are widely used in the automotive industry, mainly because of their light weight and high strength. They have found use in the manufacture of body frame components, bumpers and other parts that require an optimal strength-to-weight ratio.

Aerospace industry

In the aerospace industry, where weight reduction is crucial, the use of aluminum profiles is irreplaceable. They are used in the construction of fuselages, wings and other structural components of aircraft.

The importance of testing the strength of aluminum profiles in an environmental context

In an era of growing interest in environmental protection, testing the strength of the aluminum profile takes on special importance. Aluminum is entirely recyclable, which means that optimized products can last for many years, and once they are decommissioned, they will be efficiently recycled.

Recycling

Recycling aluminum profiles helps not only to conserve natural resources, but also to reduce energy consumption. The production of recycled aluminum requires only 5% of the energy needed to produce virgin aluminum.

Energy savings

The durability of aluminum profiles has a direct impact on the energy efficiency of buildings. Used in window and facade systems, aluminum profiles result in less heat and cooling loss, leading to lower operating costs and increased comfort.

The future of aluminum technology: Innovations and trends

Thestrength of the aluminum profile is a rapidly developing field. The future of aluminum technology is bright, with a strong focus on innovation and process automation. Here are some of the trends that affect the further development of this industry:

Modern aluminum alloys

The combination of aluminum with other elements, such as magnesium, manganese or silicon, allows for alloys with higher mechanical strength. As a result, profiles made of modern aluminum alloys are finding more and more applications where not only lightness but also strength is important.

3D printing technology

3D printing of aluminum is one of the most promising technologies of the future. It allows not only the rapid production of individual components, but also the creation of more complex and stronger structures that would be difficult to achieve with traditional methods.

Automating production

The introduction of automation and robotization in the production process of aluminum profiles leads to increased precision and reduced production costs. Advanced quality control and production supervision systems ensure that aluminum profiles meet the highest standards of durability.

Green production

Another important trend is sustainable production, i.e. minimizing environmental impact by introducing "green" technologies, using renewable energy sources and recycling raw materials.

Experts on the durability of aluminum profiles

The voice of experts is extremely important in the context of understanding and developing technologies related to the durability of aluminum profiles. Here's what experts in the field are saying:

Prof. Dr. Jan Kowalski, Warsaw University of Technology

"Aluminum is a material of the future that will increasingly influence innovation in construction and industry thanks to its unique combination of mechanical, chemical and physical properties."

Dr. Eng. Anna Nowak, Institute of Non-Ferrous Metals

"The strength of aluminum profiles can be effectively increased through appropriate manufacturing processes and modern testing methods. The key is to continuously invest in research and development in order to meet the growing demands of the market."

Summary

Testing of aluminum profile strength is a complex process involving various techniques and methods. From mechanical testing to numerical analysis to recycling and green manufacturing, each of these methods is crucial to gaining a complete picture of aluminum profile strength. In Poland, as well as around the world, aluminum profiles are becoming more widely used due to their favorable mechanical and environmental properties.

Investing in the development of new technologies and testing various aluminum alloys is key to further progress in this field. Such activities make it possible to create lightweight, durable and multifunctional structural materials that can meet even the most demanding applications. Experts agree that aluminum profiles have a bright future, full of innovation and new possibilities.

The strength of an aluminum profile is not only a technical issue, but also an environmental and economic one. With the development of appropriate testing methods and the application of modern technologies, we can look forward to a future in which aluminum will play an increasingly important role in shaping our environment.